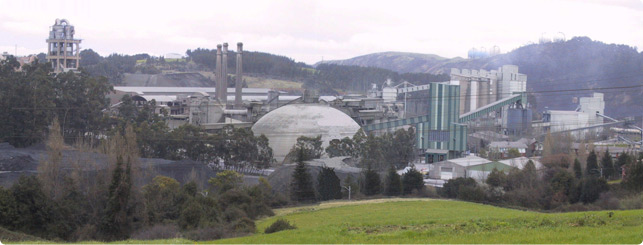

Sociedad Anónima Tudela Veguín, the first artificial cement factory in Spain, commenced production in 1898. This company is dedicated to the production of cement and other construction materials. Constant improvements in the production process and the implementation of new technology in the field of artificial cement and its derivatives have enabled our industrial sector to become leaders in Northwest Spain and to consolidate our activity at international level. This business includes the production of Cement and Lime, Slags, Quarries, Mortars, Fresh Concrete, Logistics and Distribution, Accredited Laboratories and our own maritime fleet boasting three cement carriers, one of which is amongst the most modern in the world. In the last 10 years we have invested over 140 million euro in environmental policy instruments in our four cement plants. Furthermore, after renovation in 2002, our Cement Factory in La Robla, León, has become a world leader in terms of energy and environment.

Companies which form the Industrial Sector of Corporación Masaveu

This company has three cement plants, situated in Tudela Veguín, Aboño and La Robla, with an estimated total annual capacity of 4 million tonnes. It also owns a cement-grinding mill facility in Narón (Ferrol) and holds shares in CEISA (Cementos Especiales de las Islas), the main cement producer in the Canary Islands. In 2012, we expanded our industrial activity with the acquisition of 50 per cent of Cimento Verde do Brasil from Grupo Ferroeste. We currently run a cement-grinding mill with an annual production capacity of 300,000 tonnes in a joint venture with this company. For years now, Cementos Tudela Veguín has held a firm environmental commitment, the company controls the emission of greenhouse gases with maximum efficiency and carries out continuous investments in this area; as a result our cement produces the lowest level of CO2 per tonne in Spain. In order to maximize energy efficiency, the company set up a cogeneration power plant in Aboño, in collaboration with HC Energía, with a capacity of 10 MW, making our plant the most energy efficient of its kind.

This company has three cement plants, situated in Tudela Veguín, Aboño and La Robla, with an estimated total annual capacity of 4 million tonnes. It also owns a cement-grinding mill facility in Narón (Ferrol) and holds shares in CEISA (Cementos Especiales de las Islas), the main cement producer in the Canary Islands. In 2012, we expanded our industrial activity with the acquisition of 50 per cent of Cimento Verde do Brasil from Grupo Ferroeste. We currently run a cement-grinding mill with an annual production capacity of 300,000 tonnes in a joint venture with this company. For years now, Cementos Tudela Veguín has held a firm environmental commitment, the company controls the emission of greenhouse gases with maximum efficiency and carries out continuous investments in this area; as a result our cement produces the lowest level of CO2 per tonne in Spain. In order to maximize energy efficiency, the company set up a cogeneration power plant in Aboño, in collaboration with HC Energía, with a capacity of 10 MW, making our plant the most energy efficient of its kind.

Morteros Tudela Veguín produces mortars and other construction materials, applying the experience, know-how and commitment required in activities in the Industrial Division. This business started out in 1969, with a line of production of precast concrete in the Cementos Tudela Veguín plant in Aboño. Later, in 1976, Prefasa was established as an independent company. We were pioneers in the implementation of dry mortar technology in Spain and went on to grow and expand with new plants in León, Pontevedra and Valladolid. Since then, as a result of the continuous investments and improvements carried out in Morteros Tudela Veguín, the company now has the optimal resources and capacities to meet the most demanding needs in the market. We currently have four production centres in Spain; Prefabricados Asturianos (Langreo, Asturias), Morteros y Hormigones de León (La Bañeza), General de Morteros (Valladolid) and Galaica de Morteros (Pontevedra).

Morteros Tudela Veguín produces mortars and other construction materials, applying the experience, know-how and commitment required in activities in the Industrial Division. This business started out in 1969, with a line of production of precast concrete in the Cementos Tudela Veguín plant in Aboño. Later, in 1976, Prefasa was established as an independent company. We were pioneers in the implementation of dry mortar technology in Spain and went on to grow and expand with new plants in León, Pontevedra and Valladolid. Since then, as a result of the continuous investments and improvements carried out in Morteros Tudela Veguín, the company now has the optimal resources and capacities to meet the most demanding needs in the market. We currently have four production centres in Spain; Prefabricados Asturianos (Langreo, Asturias), Morteros y Hormigones de León (La Bañeza), General de Morteros (Valladolid) and Galaica de Morteros (Pontevedra).

General de Hormigones is a founding member of the Spanish National Association of Ready Mix Concrete Manufacturers (ANEFHOP), a Spanish institution linked to several organisms whose activities are based on providing technical and legal advice on incidents which arise out of the use of these products, acting as a mediator between the manufacturer and the private company. General de Hormigones currently owns thirty plants, five of which are mobile, situated in Asturias, Galicia and Castilla y León. All of the plants belonging to General de Hormigones hold the UNE EN ISO 9001 Quality Management System Certificate. Additonally, our company was pioneer in obtaining the seal of quality INCE in 1990, and most recently was the first company in this sector in Asturias, Galicia and Castilla y León to obtain the DOR certificate (Officially Recognized Quality Certificate), entailing exhaustive daily controls of each type of certified concrete for the manufacturer, and consequently, less controls and reduced costs for our customers.

General de Hormigones is a founding member of the Spanish National Association of Ready Mix Concrete Manufacturers (ANEFHOP), a Spanish institution linked to several organisms whose activities are based on providing technical and legal advice on incidents which arise out of the use of these products, acting as a mediator between the manufacturer and the private company. General de Hormigones currently owns thirty plants, five of which are mobile, situated in Asturias, Galicia and Castilla y León. All of the plants belonging to General de Hormigones hold the UNE EN ISO 9001 Quality Management System Certificate. Additonally, our company was pioneer in obtaining the seal of quality INCE in 1990, and most recently was the first company in this sector in Asturias, Galicia and Castilla y León to obtain the DOR certificate (Officially Recognized Quality Certificate), entailing exhaustive daily controls of each type of certified concrete for the manufacturer, and consequently, less controls and reduced costs for our customers.

Correctly treated steel slag offers important uses in industry and public works. Edersa treats the slag produced by Arcelor Mittal’s factory in Veriña using a modern Ground Blast Furnace Granulation System. Calumite Ibérica then prepares the derived product for its use in the glass industry. The company’s constant commitment to quality and service was recognized when it was awarded the ISO-9001 Certificate in 1998. Likewise, the company was granted the Environmental Management Certificate ISO-14001:1996, for its environmental commitment and has also obtained OHSAS 18001:1999 Occupational Health and safety Assesment Series certification, motivating the company to continue working and improving. Escorias y Derivados (EDERSA) currently offers three products for sale: Classified Slag (HUSO ZA 25), Classified Slag (60/110 mm.) and Granulated Slag.

Correctly treated steel slag offers important uses in industry and public works. Edersa treats the slag produced by Arcelor Mittal’s factory in Veriña using a modern Ground Blast Furnace Granulation System. Calumite Ibérica then prepares the derived product for its use in the glass industry. The company’s constant commitment to quality and service was recognized when it was awarded the ISO-9001 Certificate in 1998. Likewise, the company was granted the Environmental Management Certificate ISO-14001:1996, for its environmental commitment and has also obtained OHSAS 18001:1999 Occupational Health and safety Assesment Series certification, motivating the company to continue working and improving. Escorias y Derivados (EDERSA) currently offers three products for sale: Classified Slag (HUSO ZA 25), Classified Slag (60/110 mm.) and Granulated Slag.

Estabisol was created in 1979, and provides chemical, physical and microbiological analysis, as well as all types of tests related to the research into the manufacture and control of construction materials. The Munditest laboratory, which forms part of Estabisol, was created in 1994, at a time when laboratories for health control and testing of food, water and beverages were inexistent in Asturias. It was the first laboratory to be authorized by the Ministry of Health of the Principality of Asturias. The original idea was to provide support for food companies, however the company went on to expand and now offers a variety of services such as control of waste, control in cooling towers, control systems on factory chimneys and also gives training courses. The Estabisol building includes four laboratory sections, the first three carry out the physical analyses of materials and general chemical analyses. “Laboratorio Munditest” carries out tests in various fields (foodstuffs, waters, waste and soils) and avails of both a chemical and microbiological department.

Estabisol was created in 1979, and provides chemical, physical and microbiological analysis, as well as all types of tests related to the research into the manufacture and control of construction materials. The Munditest laboratory, which forms part of Estabisol, was created in 1994, at a time when laboratories for health control and testing of food, water and beverages were inexistent in Asturias. It was the first laboratory to be authorized by the Ministry of Health of the Principality of Asturias. The original idea was to provide support for food companies, however the company went on to expand and now offers a variety of services such as control of waste, control in cooling towers, control systems on factory chimneys and also gives training courses. The Estabisol building includes four laboratory sections, the first three carry out the physical analyses of materials and general chemical analyses. “Laboratorio Munditest” carries out tests in various fields (foodstuffs, waters, waste and soils) and avails of both a chemical and microbiological department.

Siliceous material from the Bobia sand pit in León, is used as correcting sand for concrete and cements and also in the manufacture of special mortars.

Siliceous material from the Bobia sand pit in León, is used as correcting sand for concrete and cements and also in the manufacture of special mortars.

The Castañera quarry in Asturias and the Magil quarry in León, both produce limestone aggregates for use in the construction industry. Rebarco owns a high quality dolomite quarry in Andayón (Asturias) and a silica sand pit near to Ribadesella.

We would like to highlight that Masaveu Industria manages its quarries giving high priority to the reduction of the environmental impact. The company aims to optimize the available natural resources and reduce their use as much as possible, maintaining total commitment to the natural surroundings at all times.

Comibersa was established at the end of the 70’s in order to meet the logistical needs of the company today known as Cementos Tudela Veguín. Since then, they have gained experience not only in the transport of cement and other material, but also in the national and international transport of goods and in the intermediation of the provision of services of this kind, including industrial cleaning, moving material at quarries, and ship consignment amongst others. The company’s main premises are situated in the industrial estate in Falmuria (Prendes) boasting a 2,500 m2 fully equipped workshop premises and a parking area of the same size. This company currently has numerous vehicles and machines, including a dozen tractor heads, some thirty horizontal tanks for powder and liquid handling, several dumpers and cleaning equipment amongst others. Furthermore, the company boasts an integrated tracking system for managing and monitoring its fleet and for supervising transport services.

Comibersa was established at the end of the 70’s in order to meet the logistical needs of the company today known as Cementos Tudela Veguín. Since then, they have gained experience not only in the transport of cement and other material, but also in the national and international transport of goods and in the intermediation of the provision of services of this kind, including industrial cleaning, moving material at quarries, and ship consignment amongst others. The company’s main premises are situated in the industrial estate in Falmuria (Prendes) boasting a 2,500 m2 fully equipped workshop premises and a parking area of the same size. This company currently has numerous vehicles and machines, including a dozen tractor heads, some thirty horizontal tanks for powder and liquid handling, several dumpers and cleaning equipment amongst others. Furthermore, the company boasts an integrated tracking system for managing and monitoring its fleet and for supervising transport services.

Seals of quality in Masaveu Industria production centres

La Robla Factory(León)

Quality Certificates

- Best Available Techniques in the cement sector.

- AENOR N mark Product Certification, in keeping with regulation UNE-EN 197-1:2011 and UNE-EN 196-10:2008.

- In 2001, the factory obtained the AENOR Company Registry Certificate according to ISO standard 9011: 2001.

- Awarded the UNE-EN ISO 14001:2004 Environmental Management Certificate in 2007, which certifies that the company performs its activities with respect for the environment.

- In 2008, the factory obtained the Integrated Environmental Authorization, which includes the use of alternative fuels.

Naron Factory (Ferrol)

Quality Certificates

- Product Mark A+ , Quality label officially recognized pursuant to the EHE-08 Code on Structural Concrete and the RC-08 Code of Practice for Receipt of Cement.

- AENOR certified mark N product, in keeping with regulation UNE-EN 197-1:2011 and UNE-EN 196-10:2008.

- Environmental and Quality Management System certified in accordance with standards ISO 9001:2008 and ISO 14001:2004, respectively.

- Integrated Environmental Authorization IEA, since January 2007.

- The Labs have been awarded both ISO 9001:2008 Quality Management and ISO 14001:2004 Environmental Management certificates.

Tudela Veguín Factory (Aboño)

Quality Certificates

- UNE-EN ISO 9001 Quality Management System Certificate.

- UNE-EN ISO 14001 Environmental Management System Certificate.

- EC Certificate of Conformity for all cements, in compliance with European Community Council Directive 89/106/CE of 21 December 1988. All of the cement types hold the AENOR Product Certificate.

Tudela Veguín Factory (Oviedo)

Quality Certificates

- UNE-EN ISO 9001 Quality Management System Certificate.

- UNE-EN ISO 14001 Environmental Management System Certificate.

- In 2008, the factory obtained the Integrated Environmental Authorization IEA, a clear reflection of the plant’s commitment to caring for the environment.